Fully Automatic Potato Chips Plant

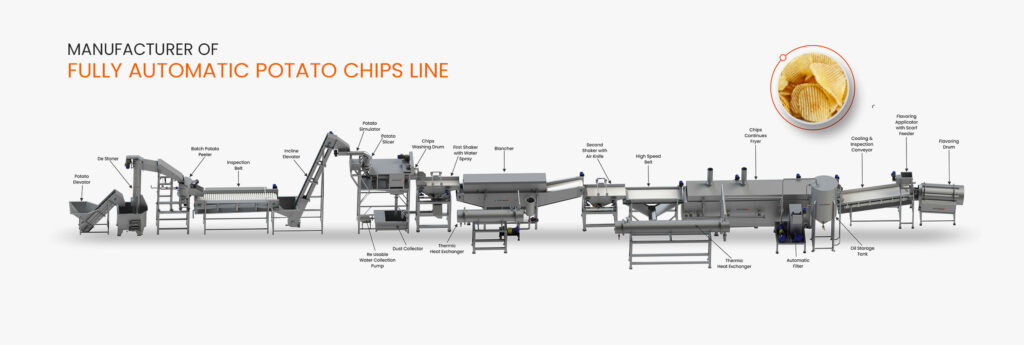

Fry And Bake Technologies Pvt. Ltd. A leading A turnkey solution for fully automatic potato chips machinery typically refers to a comprehensive package offered by a supplier or manufacturer that includes all the necessary equipment and services for setting up a complete potato chips production line. It includes everything from raw material handling to packaging. Here’s an overview of the components commonly included in a turnkey solution for potato chips machinery

The peeling mechanism of the machine removes the outer skin of the potatoes. It can utilize different methods, such as abrasive surfaces or high-pressure water sprays, to peel the potatoes effectively. The potatoes are typically loaded into a rotating drum or a chamber where the peeling action takes place.

2. Cutting

Once the potatoes are peeled, the machine can also slice them into desired shapes and sizes. The slicing mechanism may consist of various types of blades, such as rotating circular blades or adjustable slicing grids. These blades can be adjusted to achieve different thicknesses of potato slices.

1. Potato whasing and peeling machine

Potato whasing and peeling machine is used to wash and peel the potatoes, removing dirt and outer skin efficiently.

Potato peeling and slicing machines are typically electrically powered and feature rotating blades or abrasive surfaces to peel and slice potatoes. They have a feed mechanism to input the potatoes, and the machine handles the peeling and slicing process automatically.

3. Blanching

The potato slices are blanched in hot water or steam to deactivate enzymes and preserve their color.This process helps in several ways, including removing excess starch, reducing enzymatic activity, and pre-cooking the slices to achieve the desired texture and color during frying.

4.De-Watering Machine

After blanching, excess water is removed from the potato slices using a de-watering machine to ensure crispiness during frying.Removing the water helps improve the quality of the final product, such as potato chips or french fries, by ensuring crispiness during frying and preventing excessive oil absorption.

Potato dewatering machines can be designed for either batch or continuous operation. In batch machines, a specific quantity of potato slices is loaded into the drum, which is then spun to remove the water. In continuous machines, the potato slices are continuously fed into the machine and discharged while the drum rotates.

5.Potato Chips Frying Machine

Industrial-grade fryers are used for frying potato slices in hot oil. These fryers are equipped with features like temperature control, oil circulation, and automated conveying systems for efficient frying.Potato chips frying machines typically consist of a fryer tank or chamber filled with hot cooking oil. The machine includes features such as a conveyor belt or basket system to continuously feed the potato slices into the fryer and remove them once they are cooked. The machine controls the frying temperature and cooking time to ensure consistent results.

Frying machines have precise temperature control systems to maintain the oil at the desired frying temperature. The temperature typically ranges between 160-190°C (320-375°F) depending on the recipe and the desired outcome. Maintaining the correct temperature is crucial for achieving consistent frying results and avoiding undercooked or overcooked chips.

6. Oil Dehydration System

After frying, an oil dehydration system removes excess oil from the fried potato chips, enhancing their texture and reducing oil content.It helps to reduce oil degradation, prevent the formation of undesirable by-products, and maintain the flavor and crispiness of the potato chips.

The oil dehydration system typically consists of a separate unit or module integrated into the potato chips machinery. It uses various techniques to separate water or moisture from the frying oil, such as vacuum evaporation, centrifugation, or filtration.

7.Safety Considerations

Oil dehydration systems should have safety features in place, such as pressure relief valves and emergency stop buttons, to ensure the safe operation of the machinery and prevent accidents. Install appropriate machine guards, such as safety interlocks, protective barriers, or shields, to prevent access to moving parts or hazardous areas during operation. These guards help minimize the risk of accidents caused by contact with rotating blades, belts, or other machinery components.

8.Conveyor Systems

Conveyor belts or systems are used throughout the production line to transport the potatoes and potato chips between different machines and processes.

9.Control System:

A centralized control system, such as a Programmable Logic Controller (PLC) or supervisory control and data acquisition (SCADA) system, is implemented to monitor and control the entire potato chips production line, including machine parameters, process flow, and quality control.

10.Installation and Commissioning

A turnkey solution typically includes installation and commissioning services, where the supplier or manufacturer assists in setting up the machinery, ensuring proper functioning, and training the operators.

11.After-Sales Support

The supplier may provide ongoing technical support, maintenance services, and spare parts availability to ensure smooth operations and minimize downtime.