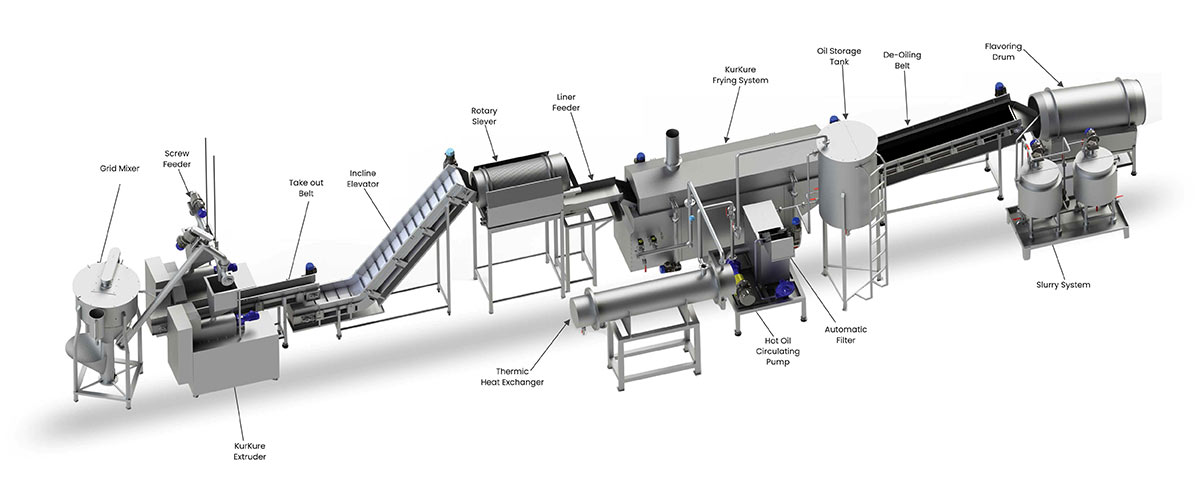

FULLY AUTOMATIC KURKURE FRYING LINE

ABOUT THIS MACHINE

The Fully Automatic Kurkure Frying System is modern Frying System which provides best frying environment which brings out the final product with best quality

Flavor Dispenser

Oil Filtration System

Flavouring Drum

Flavoring is introduced to the drum at the same time as the Kurkure or snack pellets.

The dispensing system ensures the exact amount of Flavoring in relation to the

product. with gentle movement, hence less breakage of the product.

Main Features of Fryer

- High Productivity

- Low Cost Production

- Low Fuel consumption

- Low edible oil take-up

- Low Manpower required

- Better quality finish product

- Better hygiene and working environment.

Technical Specifications

| Model | FBF-300 | FBF-500 |

| Output /in Hour | 300 Kg | 500 Kg |

| Oil Filtration System | Conveyor Type Filtration System | |

| Fuel Option | Diesel/Gas/Wood/Thermic | |

| Power Consuption in Wood | 78 Hp | 143 Hp |

| Power Consuption in Diesel/Gas/ Thermic | 75 Hp | 140 hp |

| Oil Holding Capacity In System | 450 Litre | 650 Litre |

| Length & Width Of Line | 57 ft X 10 ft | 65 ft X 11.5 ft |

| Material Of Construction | AISI 304 | AISI 304 |

GRID MIXER

The cornmeal must be of fine texture so that it produces a pleasant feel as it is eaten. Also, cornmeal with a low moisture content is used in this process. Too much moisture in the meal will render the product soggy. Cornmeal inspected for moisture content is placed into a mixing bin and sprayed with a fine mist of water as it is stirred.

Water poured directly into the meal will result in gluten formation, uneven distribution of moisture, and clumping of wet grain. When the desired consistency is achieved, the mixture is immediately extruded

KURKURE EXTRUDER

Kurkure extruder wherein we carry the process of gelatinization in a concentric cavity between two dye, one rotary with 3 blades (fingers) plus grooves, and the other one with grooves only. The action of these blades on the rotating head creates the necessary condition of pressure and heat to achieve gelatinization of the raw material.

Product is expanded and formed in a narrow gap between the two plates. Blades affixed to a circular knife support ring mounted on the outer edge of the rotor cuts to the desired size.

Incline Elevator

An elevator with small hopper to receive raw pellets. Entire construction in SS 304 with exception of standard component viz. drive motor, flighted conveyor belt, bearings etc. Belt speed regulation by VFD.

ROTARY SIEVER

The fines or small particles tend to absorb oil and flavorings and are undesirable to include in a package of cheese curls. The fines or small particles that are produced as the collets are removed by this rotary sieve. Adapted for a variety of products and can simultaneously sort into several different grading classifications

KURKUR FRYER

Product is fried beneath a submerger conveyor and taken out by a separate takeout belt on an inclined plane. For ease of cleaning conveyor frames along with top hood are lifted with help of mechanized hood lifting system. Material of construction will be stainless steel (SS304).

DE-OILING BELT

The conveyor receives Kurkur from fryer. And transports it to further process. It allows the product temperature to come to equilibrium and removing excess surface oil. Belt speed regulation by VFD. Entire construction is of stainless steel except for the standard parts.

Slurry System

Seasoning is added to the product using nozzles in the zig-zag drum to get mixed with the collates. Specially designed zig-zag drum & controlled slurry application ensures uniform coating.

FLAVOUR DRUM

It is a rotary horizontal drum, which blends the fried product and flavour together so that the flavour is evenly covered as far as practically possible. The drum is made such that its degree of inclination can be adjusted. The drum is also provided with inwardly projecting product lifters. Speed of rotation of drum is variable and entire construction is of SS304 except standard components.

Craft the Perfect Kurkure with Fry & Bake's Kurkure Making Machine

Fry And Bake Technologies Pvt Ltd, the leading Kurkure making machine manufacturer, provides a Fully Automatic Kurkure Frying Line and a Kurkure Frying Machine for high-quality snack manufacturing. Our Kurkure Making Machine has an innovative Flavoring Dispenser for accurate salt and flavoring dosing, as well as a controlled stainless steel hopper and dedicated display. The Conveyor Filter eliminates starch particles from frying oil, hence increasing product shelf life. Kurkure adds flavor to the drum in exact amounts and with gentle movement, reducing breaking. Contact us for the best Kurkure machine solutions.