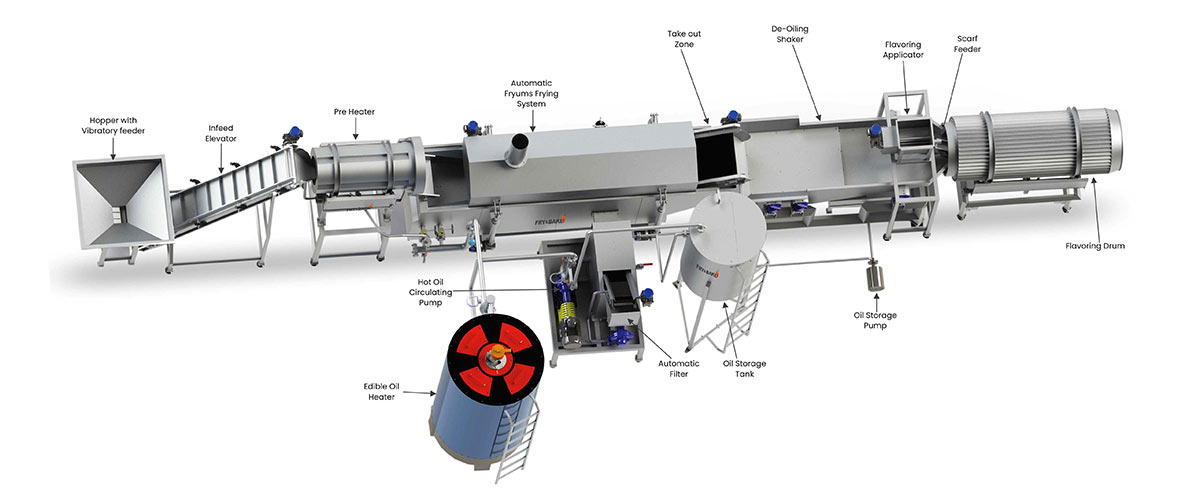

FULLY AUTOMATIC PELLETS FRYING LINE

ABOUT THIS MACHINE

Flavor Dispenser

Flavoring Drum

Oil Filtration System

Main Features of Fryer

- High Productivity

- Low Cost Production

- Low Fuel consumption

- Low edible oil take-up

- Low Manpower required

- Better quality finish product

- Better hygiene and working environment.

Technical Specifications

| Model | FBF-300 | FBF-500 | FBF-700 | FBF-1000 | FBF-1500 |

| Output /in Hour | 300Kg | 500Kg | 700Kg | 1000Kg | 1500 Kg |

| Fuel Option | Diesel/Gas/Wood/Thermic | ||||

| Oil Filtration System | Manual | Conveyor Type Filtration System | |||

| Power Consuption in Wood | 13.5 Hp | 14 Hp | 19.5 Hp | 22.5 Hp | 24.5 Hp |

| Oil Holding Capacity In System | 450 Litre | 650 Litre | 800 Litre | 1000 Litre | 1150 Litre |

| Length & Width Of Line | 56ft X 8.5ft | 60ft X 9.5ft | 66ft X 10.5ft | 70ft X 11.5ft | 73.5ft X 13ft |

| Material Of Construction | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 |

HOPPER VIBERATOR

A buffer hopper to feed raw pellets. Entire construction in SS 304 with exception of standard component viz. drive motor, Vibrator etc.

FEED ELEVATOR

An elevator with small hopper to receive raw pellets. Entire construction in SS 304 with exception of standard component viz. drive motor, flighted conveyor belt, bearings etc. Belt speed regulation by VFD.

PRE-FRYER

To evenout moisture content in raw pellets prior to frying. All Stailnless steel construction except standard components viz. drive rolls system, drive motor, bearings etc.

PELLET FRYER

Product is fried beneath a submerger conveyor and taken out by a separate takeout belt on an inclined plane. For ease of cleaning conveyor frames along with top hood are lifted with help of mechanized hood lifting system. Material of construction will be stainless steel (SS304).

DE-OILING CONVEYOR

The conveyor receives pellets from fryer. And transports it to further process. It allows the product temperature to come to equilibrium and removing excess surface oil. Belt speed regulation by VFD. Entire construction is of stainless steel except for the standard parts.

FLAVOUR DRUM

It is a rotary horizontal drum, which blends the fried product and flavour together so that the flavour is evenly covered as far as practically possible. The drum is made such that its degree of inclination can be adjusted. The drum is also provided with inwardly projecting product lifters. Speed of rotation of drum is variable and entire construction is of SS304 except standard components.

SCARF TRAY

Vibratory Scarf Tray for even spraying of flavoring.