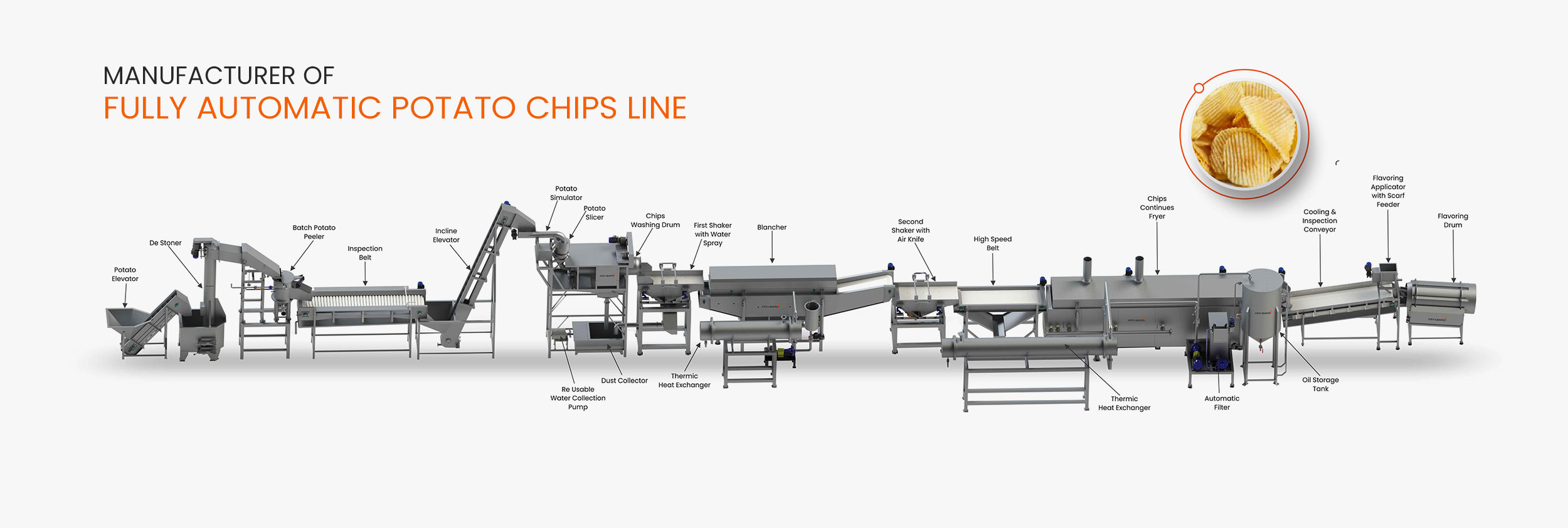

FULLY AUTOMATIC POTATO CHIPS LINE

ABOUT FULLY AUTOMATIC POTATO CHIPS LINE

The professional fully automatic potato chips production line is specially designed for processing potatoes into delicious potato chips, potato crisps or French fries with excellent quality and less fat pickup.

ABOUT THIS MACHINE

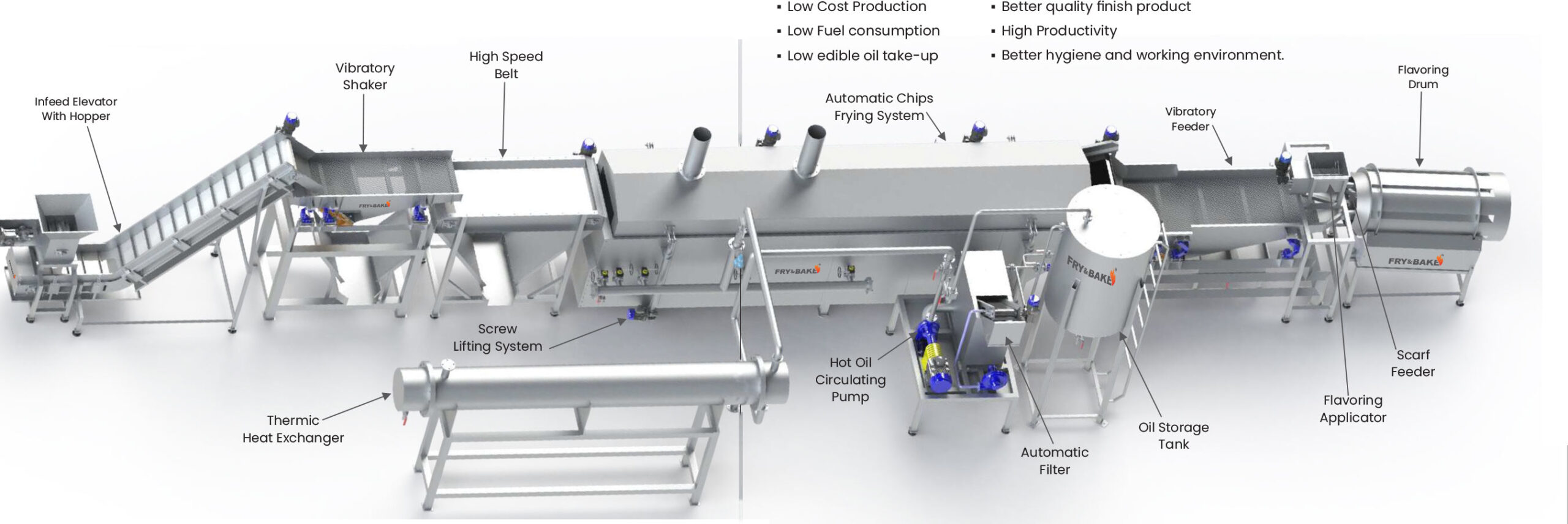

The professional semi automatic potato chips line is specially designed for processing potatoes into delicious potato chips, potato crisps or French fries with excellent quality and less fat pickup.

Innovative Design

Continuous Fat Filtration System

Flavouring Drum

Main Features of Fryer

- High Productivity

- Low Cost Production

- Low Fuel consumption

- Low edible oil take-up

- Low Manpower required

- Better quality finish product

- Better hygiene and working environment.

How We Works

Technical Specifications

| Fully Automatic Potato Chips Line | Semi Auto Potato Chips Line | ||||

| Model | FBF-300 | FBF-500 | FBF-1000 | FBF-100 | FBF-200 |

| Output /in Hour | 300 Kg/Hr. | 500 Kg/Hr. | 1000 Kg/Hr. | 100 Kg/Hr. | 200 Kg/Hr. |

| Edible Oil Holding Capacity | 900 Ltrs | 1600 Ltrs | 3000 Ltrs | 550 Ltrs | 750 Ltrs |

| Power Required with Blancher | 65 HP | 85 HP | 122 HP | NA | NA |

| Power Required Without Blancher | 52 HP | 65 HP | 102 HP | 19 HP | 22 HP |

| Water Reuired | 2000 Ltrs/Hr | 3500 Ltrs/Hr | 6000 Ltrs/Hr | 500 Ltrs/Hr | 1000 Ltrs/Hr |

| Floor Space | 3000 sq. ft | 4000 sq. ft | 5000 sq. ft | 1200 sq. ft | 1500 sq. ft |

| Length Of the Line | 140 ft | 160 ft | 160 ft | 51 ft | 55 ft |

| Material Of Construction | AISS-304 | AISS-304 | AISS-304 | AISS-304 | AISS-304 |

INFEED ELEVATOR

The equipment receives potatoes from sacks / container in bulk and feeds to the Dust Remover at a uniform rate so as to have proper product throughput. It consists of a flighted plastic conveyor belt of modular design and a buffer hopper. The drive motor is variable speed type. All stainless steel (AISI 304) construction except standard components viz. drive motor & bearings.

Grader

Single size grading of potatoes. A rotary drum with bottom tray. Drive motor is fix speed. All stainless steel (AISI 304) construction except standard components.

Destoner

The equipment removes stones and mud normally adhered to potato surface to make a safer slicing operation. Potatoes are received in turbulent water bath and are conveyed by a screw for further operation. All stainless steel (AISI 304) construction except standard components viz. drive motor & bearings.

Peeler

The equipment peels potatoes with minimum peel loss. Peeling is carried out by abrasive coated drum. Peeled Potatoes move into an outfeed chute by automatic gate opening. An infeed hopper controls feeding of potatoes inside the peeler. Peel waste is carried away with this water through drain and can be collected at the bottom. Entire construction is of stainless steel (AISI 304) with the exception of standard components viz. drive motor & bearings, air cylinders etc. The design reflects high sanitation emphasis.

Roller Inspection Conveyor

A conveyor belt for the trimming of defective portion / oversized potatoes. PVC roller belt driven by side chainis used to inspect potatoes. Defective potatotes to be trimmed on side tables provided. Entire construction is of stainless steel (AISI 304) with the exception of standard components viz. drive motor, roller belt & bearings.

SLICE FEED ELEVATOR

The equipment receives potatoes from inspection conveyor and feeds to the Slicer at a uniform rate so as to have proper product throughput. It consists of a flighted plastic conveyor belt of modular design and a buffer hopper at the infeed. The drive motor is variable speed type. All stainless steel (AISI 304) construction except standard components

SLICE WASHER

Equipment performs washing of slices so that surface starch contents are reduced to minimal. Potato slices from slicer enter into a continuously rotating tumbler tube along with water. All stainless steel (AISI 304) construction except standard components

SLICE WASHER SHAKER

Washed slices from tumbler are dewatered on a vibrator screen. The screen size is such that nubbins are separated and collected on a perforated tray located at the bottom. All stainless steel (AISI 304) construction except standard components.

SLICE WASHER SHAKER

Washed slices from tumbler are dewatered on a vibrator screen. The screen size is such that nubbins are separated and collected on a perforated tray located at the bottom. All stainless steel (AISI 304) construction except standard components.

BLANCHER

Slices travel in a turbulent hot water bath. Turbulence of water is just enough so as to have optimal blanching of the slices without any damage to its physical state. The product moves in compartmentalized belt so that each slice gets uniform blanching. Water is recirculated by a pump. Steam is injected directly into the tub. Temperature of the hot water is controlled by a steam control valve whereas the product travel time is regulated by a variable speed motor. In order to avoid coagulation make up water is continuously added to the bath. All stainless steel construction including belt except standard components.

SHAKER

Equipment removes excess surface water from the slices and separates them prior to frying. It consists of a vibrator and drain pan where water gets accumulated and drained. The amplitude of vibration is so adjusted that it does not break the slices. All stainless steel construction except standard components.

HIGH SPEED BELT

A conveyor belt running at high speed for feeding of slices in the fryer. It avoids coagulation of slices prior to feeding in fryer. The Belt is imported plastic modular type. Drive motor is fix speed type. Entire construction is of stainless steel (AISI 304) with the exception of standard components.

FRYER

Equipment is a combination of dip frying with multiple oil inlet, with combination of paddles and submerger belt. The flow of oil ensures a laminar flow of oil for uniform frying. The equipment is designed to have a low oil holding capacity in order to achieve low oil turnover ratio. Complete enclosure is comprising of paddles &submergerbelt , takeout belt, continuous oil filter & oil holding tank to ensure automatic level control during frying. Belts speed can be varied by variable frequency drives, for frying time adjustments. Entire design allows easy cleaning of the system as top hood along with paddles &submerger conveyor can be lifted up with help of motorized screw jacks system provided.

The continuous oil filtration is carried out by a belt type filter, which keeps the frying media clean. Apart from controlling the oil level, the tank also serves the purpose of overnight storage. After frying the chips are received by takeout cum temperature equalization belt which removes excess surface oil from the chips. A PID temperature controller, controls temperature of the oil. Entire system is complete with interconnecting piping and valves & its construction is of stainless steel (AISI 304) including belts except for the standard components.

VIBRATORY INSPECTION CONVEYOR

A vibratory conveyor for the inspection of fried chips. Vibration thru unbalanced motors. Entire construction is of stainless steel (AISI 304) with the exception of standard components

FLAVOUR DRUM

It is a rotary horizontal drum, which blends the fried product and flavour together so that the flavour is evenly covered as far as practically possible. The drum is made such that its degree of inclination can be adjusted. The drum is also provided with inwardly projecting product lifters. Speed of rotation of drum is variable and entire construction is of SS304 except standard components.

APPLICATOR

Flavour is sprinkled in proportion on chips by SCARF PLATE. Coagulation of flavour is avoided by mixing blade. A variable speed motor adjusts feed rate of the flavour. Entire system construction is of stainless steel (AISI 304) construction including belts except standard components.