“Achieving Quality and Efficiency: The Role of an Automatic Kurkure Line in Snack Production”

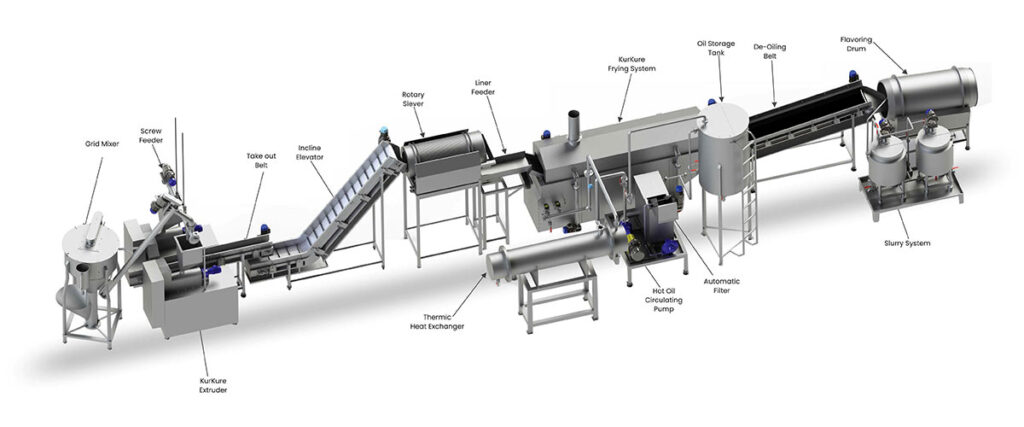

Introduction of fully automatic kurkure production line

In the competitive snack industry, companies strive to deliver high-quality products efficiently to meet consumer demand. One such company leading the way is Fry and Bake Snacks, known for its commitment to excellence and innovation. This article explores the significant role played by an automatic Kurkure line in Fry And Bake’s snack production process, highlighting the benefits it brings in terms of quality and efficiency.

1.Streamlined Production Process:

Fry And Bake Snacks understands the importance of optimizing production processes to deliver snacks promptly without compromising on quality. The introduction of an automatic Kurkure line has revolutionized their snack production. This advanced system integrates various stages of Kurkure manufacturing, enabling a streamlined process from raw material preparation to packaging.

2. Consistent Quality Control:

Maintaining consistent quality is a critical factor in the success of any snack brand. The automatic Kurkure line at Fry And Bake Snacks incorporates advanced technologies that ensure precise control over key manufacturing parameters. This control guarantees uniform product quality, including texture, taste, and crunchiness, throughout the production process.

3. Enhanced Food Safety:

Food safety is of paramount importance in the snack industry. By implementing an automatic Kurkure line, Fry And Bake Snacks has bolstered their commitment to delivering safe products to consumers. The system includes rigorous quality checks and monitors critical control points, reducing the risk of contamination and ensuring compliance with stringent food safety regulations.

4.Increased Production Efficiency:

Efficiency is crucial in meeting the ever-growing demand for snacks. The automatic Kurkure line has significantly improved production efficiency at Fry And Bake Snacks. The integration of automation and advanced machinery has reduced manual labor requirements, minimized downtime, and increased throughput. As a result, the company can produce larger volumes of Kurkure snacks in less time, enabling them to meet market demands more effectively.

5. Product Innovation and Customization:

The flexibility of an fully automatic Kurkure line allows Fry And Bake Snacks to explore new flavors, shapes, and variations of Kurkure snacks. With the ability to quickly adjust settings and parameters, the company can introduce exciting product innovations and cater to diverse consumer preferences. This adaptability gives Fry And Bake Snacks a competitive edge and strengthens their brand presence in the market.

6. Sustainability and Waste Reduction:

Fry And Bake Snacks acknowledges the importance of sustainability in today’s world. The automatic Kurkure line promotes sustainability by optimizing the use of resources and reducing waste. The system enables precise ingredient measurements, minimizing raw material wastage. Additionally, energy-efficient machinery and improved process control contribute to Fry And Bake Snacks’ environmental stewardship.

The implementation of an automatic Kurkure line has proven to be a game-changer for Fry And Bake Snacks, enabling them to achieve superior quality and enhanced production efficiency. By integrating advanced technology, the company has streamlined its production processes, ensured consistent quality control, and increased its ability to meet market demands. The flexibility and innovation provided by the automatic Kurkure line allow Fry And Bake Snacks to stay ahead of the competition, while their commitment to sustainability reinforces their position as an industry leader.

.