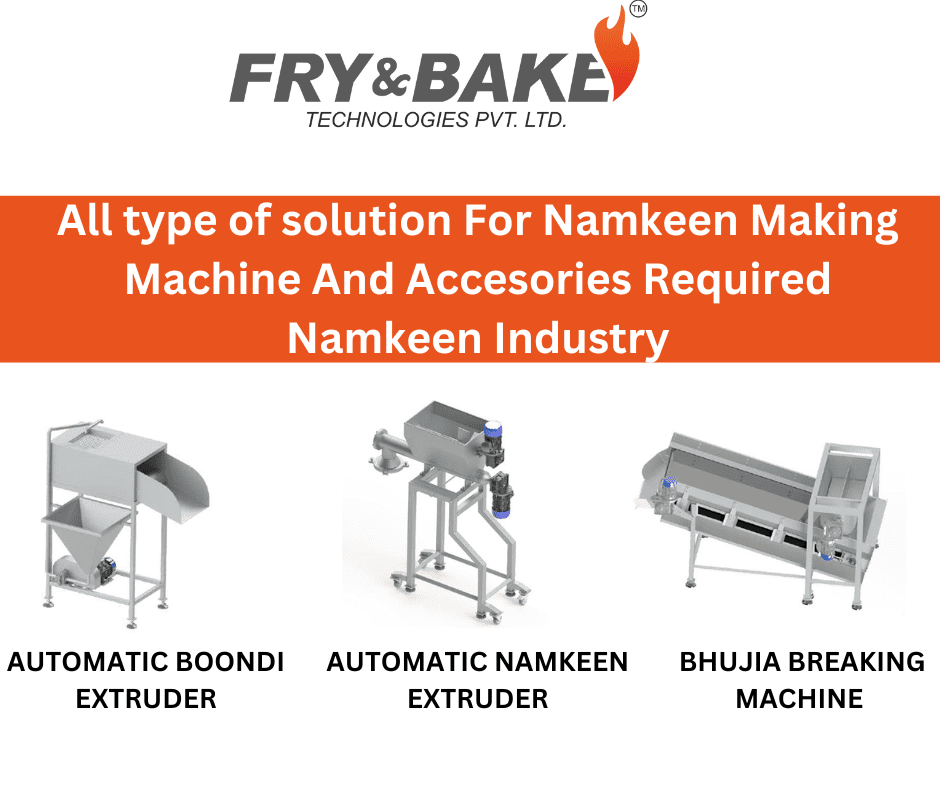

Solution For Namkeen Making Machine and Accessories Required Namkeen Industry

Fry and Bake Technologies Pvt. Ltd. specializes in manufacturing namkeen making machines with a focus on low labor cost, installation services, limited production cost, and including all the necessary accessories. Namkeen making machines are used to automate the process of producing namkeen snacks, providing efficiency and consistency in production. The inclusion of accessories ensures that the machine is equipped with everything required for the namkeen-making process. By offering a solution that addresses labor costs and provides installation services, Fry And Bake Technologies Pvt. Ltd. aims to make it easier and more cost-effective for snack manufacturers to set up and operate their namkeen production lines. The focus on limited production cost suggests that the machines are designed to optimize resources and minimize operational expenses. To get detailed information about the namkeen making machines manufactured by Fry And Bake Technologies Pvt. Ltd. , We are recommend contacting the company directly through their official website or reaching out to their customer service. We have be able to provide you with specific information regarding the features, capabilities, and pricing of their namkeen making machines, as well as any other inquiries you may have.

Fry And Bake Technologies Pvt. Ltd. is a leading manufacturer specializing in the production of namkeen making machines. With a strong focus on cost-effectiveness and efficiency, their machines are designed to minimize labor costs while providing easy installation, limited production costs, and including all the necessary accessories. In this comprehensive article, we will delve into the various aspects of Fry And Bake Technologies Pvt. Ltd.’s namkeen making machines, exploring their features, benefits, and how they revolutionize the snack food industry.

Namkeen, a popular category of savory Indian snacks, has gained immense popularity both domestically and internationally. As demand continues to rise, snack manufacturers face the challenge of meeting this growing market while keeping production costs under control. Recognizing this need, Fry And Bake Technologies Pvt. Ltd. has developed innovative namkeen making machines that address these concerns effectively.

One of the standout features of Fry And Bake Technologies Pvt. Ltd.’s automatic namkeen fryer is their ability to minimize labor costs. With advancements in automation technology, these machines streamline the production process, reducing the reliance on manual labor. By automating tasks such as mixing, shaping, frying, and seasoning, manufacturers can significantly reduce the number of workers required for production. This not only cuts down on labor expenses but also enhances operational efficiency and consistency in product quality.

Additionally, Fry And Bake Technologies Pvt. Ltd. understands the importance of hassle-free installation for their customers. The company provides comprehensive installation services, ensuring that the namkeen making machines are set up and operational in the shortest possible time. Their team of experts guides clients through the installation process, making it seamless and efficient. This allows snack manufacturers to quickly integrate the machines into their production lines, minimizing downtime and maximizing productivity.

Another key benefit offered by Fry And Bake Technologies Pvt. Ltd.’s namkeen making machines is limited production costs. By employing state-of-the-art technology, these machines are designed for optimal resource utilization. We are minimize energy consumption, optimize ingredient usage, and reduce wastage. This results in lower production costs and improved profitability for snack manufacturers. The machines’ efficient heating and frying mechanisms also contribute to energy savings, further enhancing cost-effectiveness.

Moreover, Fry And Bake Technologies Pvt. Ltd. goes above and beyond by providing all the necessary accessories required for namkeen production line. These accessories include mixing bowls, shaping tools, frying baskets, seasoning applicators, and packaging equipment. By offering a complete package, Fry And Bake Technologies Pvt. Ltd. ensures that their customers have everything they need to start producing namkeen immediately. This eliminates the hassle of sourcing individual components and guarantees a seamless production process from start to finish. The automatic namkeen fryer manufactured by Fry And Bake Technologies Pvt. Ltd. are highly versatile, accommodating various types of namkeen snacks. Whether it’s sev, bhujia, chivda,boondi or other popular namkeen varieties, these machines can handle a wide range of recipes and ingredients. We are offer customization settings, allowing snack manufacturers to adjust parameters such as frying time, seasoning quantity, and texture to achieve the desired product characteristics. This flexibility enables producers to cater to different consumer preferences and market demands. Furthermore, Fry And Bake Technologies Pvt. Ltd.’s namkeen making machines are designed with hygiene and food safety in mind. We are constructed using high-quality materials that meet industry standards for food processing equipment. The machines feature smooth surfaces, removable parts, and easy-to-clean components, facilitating thorough cleaning and maintenance. This ensures that the namkeen produced remains safe and free from contaminants, meeting the stringent quality requirements of the snack food industry. Fry And Bake Technologies Pvt. Ltd. has emerged as a leading manufacturer of namkeen making machines in the snack food industry. With their focus on low labor costs, installation services, limited production costs, and inclusion of all necessary accessories, they provide a comprehensive solution for snack manufacturers. By leveraging automation, these machines optimize operational efficiency, minimize labor expenses, and enhance product consistency. Their versatility, energy efficiency, and adherence to food safety standards further contribute.

⇒Accessories required for automatic namkeen fryer

Namkeen making machines require various accessories to facilitate the production process effectively. Here are some essential accessories that are typically included or required for namkeen making machines:

- Mixing Bowls: These bowls are used for combining ingredients and mixing them thoroughly to create the namkeen dough or batter. They should be food-grade, easy to clean, and resistant to wear and tear.

- Shaping Tools: Namkeen snacks come in different shapes and sizes. Shaping tools such as nozzles, discs, or molds are used to shape the namkeen dough or batter into desired forms like strands, loops, or clusters.

- Frying Baskets: These baskets are used to hold the namkeen while it is being fried. They should have a sturdy construction, suitable mesh size to allow oil drainage, and heat-resistant handles for safe handling.

- Seasoning Applicators: Namkeen snacks often require seasoning to enhance their flavor. Seasoning applicators such as sprinkle nozzles or rotating drums are used to evenly distribute the seasoning or flavoring agents onto the fried namkeen.

- Packaging Equipment: Once the namkeen snacks are ready, packaging equipment is used to pack them in suitable containers or pouches. This may include weighing scales, sealing machines, labeling systems, and conveyor belts for efficient packaging and product presentation.

- Oil Filtration System: Namkeen frying involves the use of oil, which needs to be filtered periodically to remove impurities and maintain product quality. An oil filtration system helps to remove particles, debris, and excess oil from the frying unit, extending the oil’s lifespan and reducing operational costs.

- Cleaning Tools: Namkeen making machines require regular cleaning to ensure food safety and maintain hygiene standards. Cleaning tools such as brushes, scrubbers, and cleaning solutions are necessary to keep the machine and its components clean and free from residue.

- Spare Parts and Maintenance Tools: It’s crucial to have spare parts and maintenance tools on hand for timely repairs and maintenance. These may include replacement filters, gaskets, heating elements, control knobs, and other components that are subject to wear and tear during machine operation.